Our main processes include cutting, laminating, moulding and extruding.

-

Cutting

Our main cutting processes include die-cutting, roll-slitting, hot-wire cutting and precision cutting of different materials to required lengths. Our computerized digital-control systems ensure optimized material use, shorter production times and increased productivity.

-

Laminating

Our laminating processes allow us to apply adhesive onto selected materials and thereby render them self-adhesive. It also allows us to construct different material blends to offer optimum sealing, gasketing, insulating and soundproofing solutions.

-

Moulding

We use compression or injection moulding processes depending on the type and complexity of the part to be manufactured, and the materials selected.

-

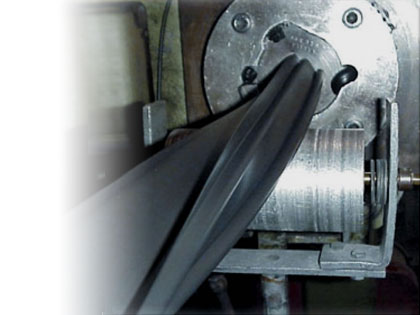

Extruding

Our extruded products are available in market-standard sizes or they can be customized to suit your needs and specifications. Products can be precision-cut to your shape and size requirements, or they can be bonded or vulcanized depending on the final dimensions desired.